We provide 3D printing services using only industrial 3D printers. As this is a professional equipment, it shows the highest quality of produced items.

Durable parts of any geometric shape with high accuracy are printed within 1-3 days.

We produce prototypes for automotive, aerospace, medicine and construction industries as well as for designers and housewives.

Fine 3D printed prototypes and solid parts help you quickly assess the ergonomics, functionality and design of any product. Turning to us, you increase the flexibility, effectiveness and competitiveness of your business and minimize costs!

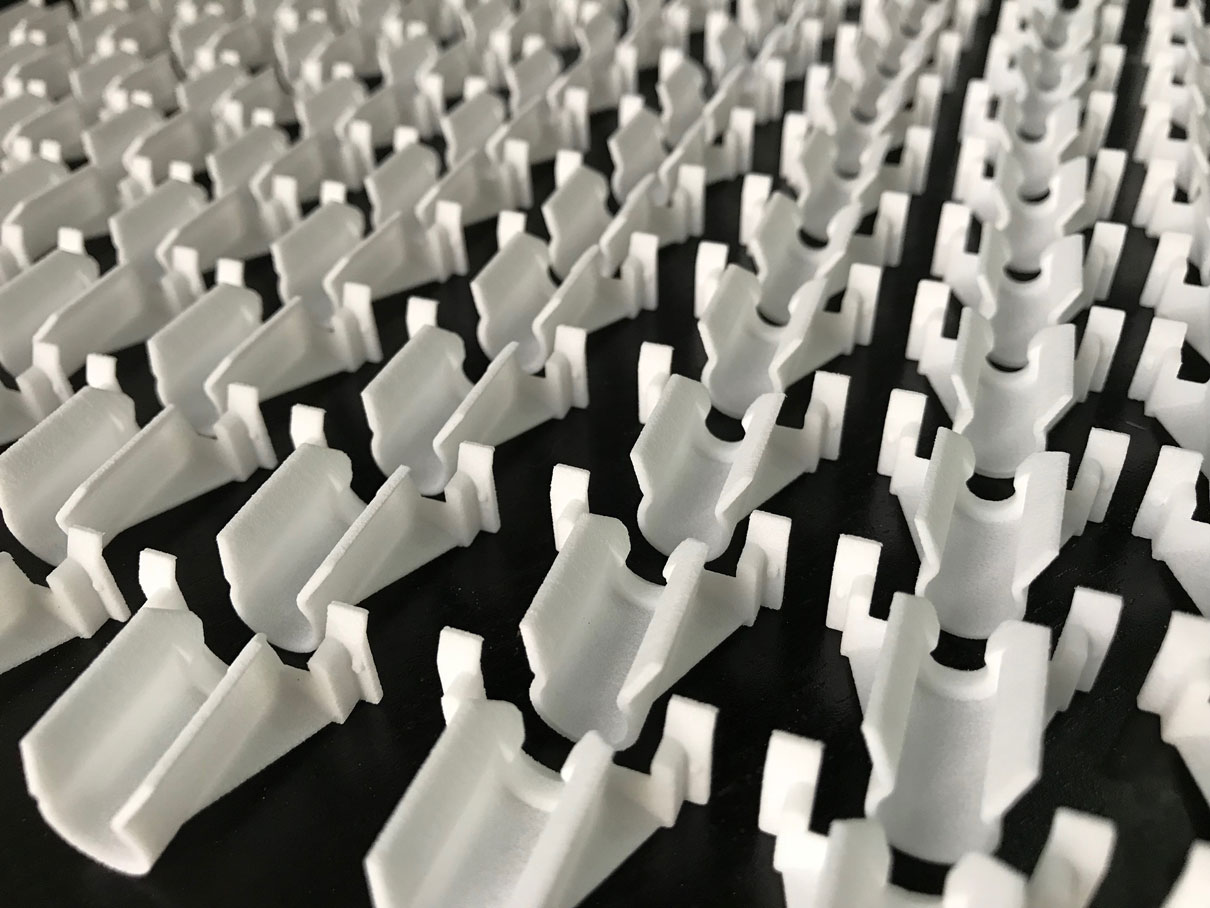

During several years we have been effectively cooperating with factories and design bureaus towards producing (3D printing) batches of small and medium size parts.

We have the best industrial machines and our experience to help you produce low volume plastic parts from a few items to thousands just for one 3D printing process, which usually takes 2-3 days.

This is the fastest way of production nowadays. You don’t need to spend time on molding. You just get ready-to-use full functionality parts at once. Time is money. Save it!

In most cases cost of each product in a batch will be cheaper. We provide a flexible system of discounts.

We offer a free vibro-polishing service for polyamide (nylon) parts in the vibro-polishing drum. This is the fastest and easiest way to make your objects’ surface smooth and nice just like an injection moulded part.

We recommend vibro-polishing for part size between 4 and 15 cm.

The parts are put in the drum together with the washing solution and ceramic abrasive and the process starts. It takes 6-12 hours, depending on which surface quality you need.

Please, notice that polishing can reduce the external dimensions up to 0.1 mm.

Polyamide (nylon) 3d printed parts are white, but there is no problem turning them to any other colour matching RAL.

One of the ways to change colour is dyeing with aniline pigments, which are used in the textile industry. The technology is quite simple, but needs a lot of practice. We dissolve the pigment in boiling water, add table vinegar and keep it boiling for a while, stirring. The boiling time is 10-90 minutes. After the process parts should be dried well and coated with colourless acrylic lacquer to close pores. It is important to note that polyamide (nylon) does not change its properties during dyeing. We can get dozens or even hundreds of coloured prototypes at once.

We also colour polyamide (nylon) parts with acrylic aerosols. This process includes several stages:

priming, grinding and spraying. These operations are done manually for every item and take longer time than dyeing.

Our sample kits are free. We are happy to send you a set of small, but demonstrative parts made of different materials: polyamide (nylon), photopolymer and ABS plastic. So you can compare three types of materials and technologies to make the right decision about prototyping.

Our sample kit is the simplest way for you to understand all the features of industrial 3D printing. Your questions will be answered.